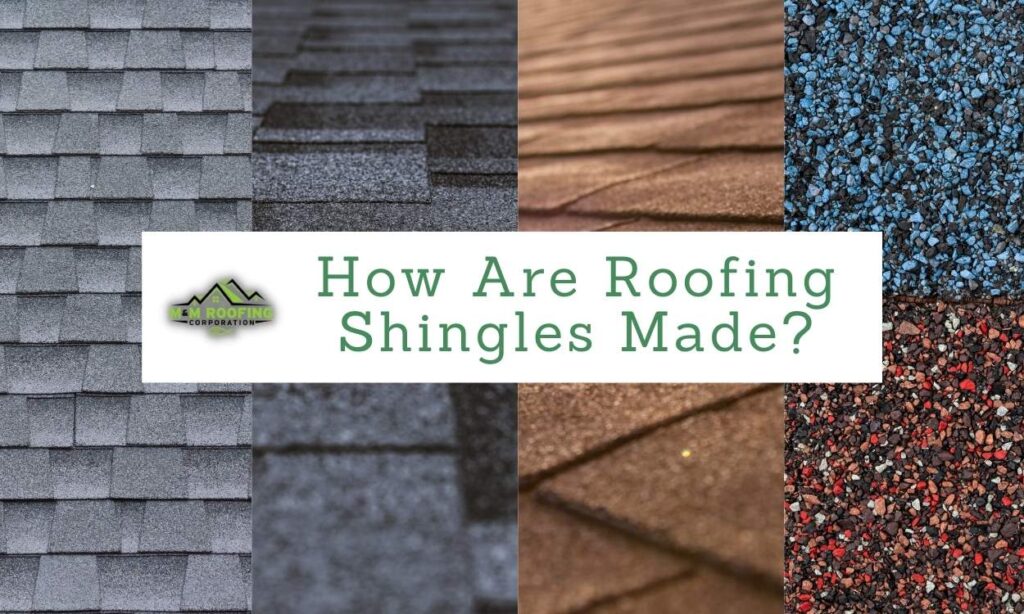

Before describing the process of making shingles, let’s first discuss the different types of materials. The four most common types of shingles are Asphalt, Fiberglass, Wood, and Composite. After identifying their different properties, these materials are used to make shingles. You may already have some idea about the difference between them. Keep reading to learn more! Listed below are the three main types of materials used to make shingles.

Asphalt

How are roofing shingles made? There are several important processes involved. The most important of these is the manufacture of asphalt shingles. Asphalt shingles are made of two main ingredients: stone granules and asphalt. Stone granules are the visible part of asphalt shingles. They are made by crushing hard rock and applying them to the asphalt layer. Granules may be colored or reflective to attract light and act as algae repellents. Architectural shingles are built from several layers of shingles. The top layer is cut specifically to simulate the desired design, and the shingles then adhere to the bottom layer. This ensures a continuous layer of protection.

Fiberglass

If you live in an area with severe weather, you might consider installing fiberglass shingles. These shingles require very little maintenance and are ideal for coastal areas. They also come in various colors, making them a versatile choice. These shingles are often cheaper than metal shingles and are easier to install. Read on to learn more about the advantages of fiberglass shingles. This type of roof is extremely durable and will last for up to 50 years.

Wood

The simplest answer to the question, “How are roofing shingles made from wood?” is simple enough. Wood shingles are thin, tapered pieces of wood that cover roofs and walls to protect them from the elements. Wood shingles were traditionally split from long, straight bolts of wood. They are sanded evenly and are usually 18-24 inches wide. Some are irregular and irregularly shaped, and there are different grades of wood shingles.

Composite

Composite roofing shingles are manufactured from plastic, HDPE, or polymer blends. These are often referred to as synthetic, fake, or engineered shakes. Some are single-width, while others come in sorted bundles of pieces that range from 4″ to 12 inches. Many are made to mimic the look of various roofing materials, including wood shakes, slate, or concrete tile. While these products aren’t as durable as real shingles, they provide a more attractive and durable roof than a standard asphalt-based shingle.

Release film

You’re not alone if you have ever wondered how roofing shingles are manufactured. Several manufacturers use release film to protect their shingles against premature activation of the asphalt sealant. This protective film is located on the back of the shingles and acts as a barrier between the shingle and the roof. Once installed, the release film remains in place, protecting your roof against premature activation of the asphalt sealant.

Granules

Granules are an integral part of the production process of roofing shingles. These pieces of material make the shingles durable and protect the roof from weather damage. In addition to granules’ aesthetic appeal, they also help prevent the growth of blue-green algae, which causes dark streaks on roofs. To find out how granules help roofing shingles stay cooler, read on.

Underlayment

There are two basic types of underlayment. It Felt paper and synthetic. The former is generally cheaper and more absorbent. However, felt can become wrinkled or ripped easily, making it difficult to install shingles. Both types effectively protect the roof from water damage, but the pros and cons of each will depend on the climate and the type of roofing shingles used. Listed below are some tips for choosing the right underlayment for your roof.

Call M & M Roofing Corp if you need a professional Roofing Shingles Installation; we service all New Jersey Area.